The future of green technology is closer than ever. So close that you can see it for yourself at Syracuse University.

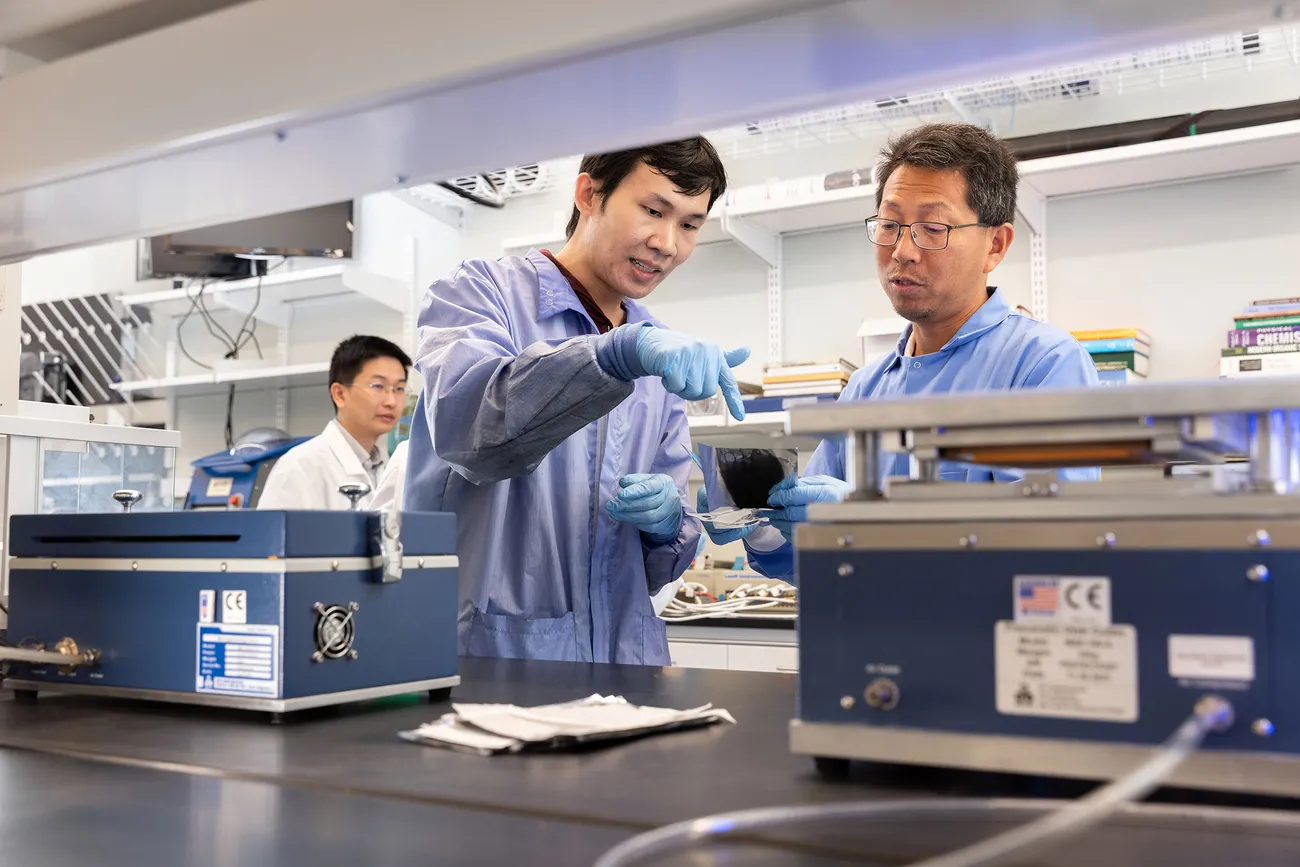

There in the College of Engineering and Computer Science (ECS), Professor Quinn Qiao (above, at left/right) is ushering in a new era of battery power and energy storage technology. He and his students design solid-state batteries—cleaner, safer and more affordable alternatives to traditional lithium-ion batteries.

“Solid-state batteries are the holy grail of energy research,” says Qiao, who teaches in the mechanical and aerospace engineering (MAE) department. “Compared to conventional batteries, they have a greater storage capacity and leave a smaller carbon footprint.”

Public interest in sustainability and low greenhouse gas emissions is at an all-time high. Qiao is capitalizing on this trend through his involvement with the Center for Solid-State Electric Power Storage (CEPS) and the Upstate New York Energy Storage Engine—inter-institutional research hubs supported by the National Science Foundation. “Our work is of vital interest to consumers, investors and governments.”

Qiao and his students thrive on front-line machinery and equipment. His newly renovated lab in Link Hall reflects a broad commitment to experiential learning and new technologies. The space also is a physical expression of ECS’ ambitious growth aspirations. “It’s a rich research ecosystem, all under one roof,” he says.

Synthesizing Opportunity

Professor Quinn Qiao gauges a coin-cell battery’s performance by repeatedly charging and discharging it over time—a process known as cycling.

To appreciate Qiao’s research is to understand how batteries work. A battery contains one or more cells that convert chemical energy into electric energy, explains the former South Dakota State professor, who joined Syracuse’s faculty in 2020. “This happens through reactions, where electrons filled with energy move between different materials.”

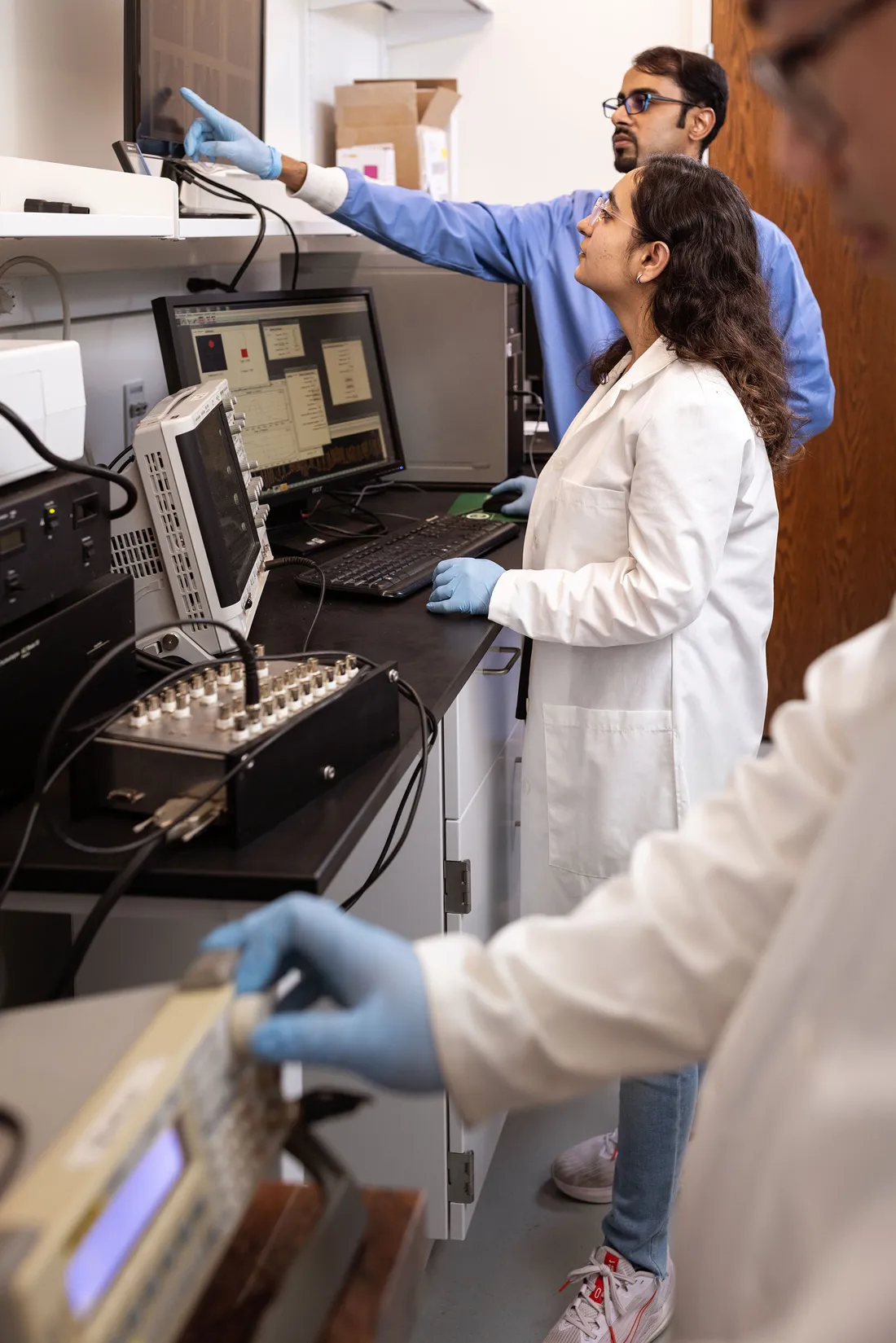

“Link Hall is like one-stop shopping for research and design,” says Muhammad Bilal Faheem Sattar, a Ph.D. candidate in mechanical and aerospace engineering. He and Vanshika, a Ph.D. candidate in chemistry, are reviewing atomic force microscopy images.

Of the many shapes, sizes and formats of batteries, lithium-ion batteries are among the most common. Their quick recharge time and long cycle life have made them synonymous with battery electric vehicles (EVs) and consumer appliances. But liquid-electrolyte-filled cells are environmentally harmful and potential fire hazards.

Enter solid-state batteries, whose cells use solid electrolytes to transport lithium ions between electrode conductors. Despite their small size, solid-state batteries can store up to 10 times more energy than their rechargeable counterparts.

Muhammad Bilal Faheem Sattar, a Ph.D. candidate in MAE, studies the chemical compositions of batteries. “I want to make batteries environmentally sustainable,” he says, noting his interest in flat, flexible “pouch batteries.” “At Syracuse, I have access to instruments for device fabrication and characterization as well as tools for evaluating the corresponding devices.”

Such equipment includes gloveboxes, enabling Sattar to engineer substances in a pure, inert atmosphere; spectrometers for observing how materials interact with electromagnetic waves; multiple battery testing stations; and several electron microscopes.

Sattar appreciates having everything at his fingertips. “Link Hall is like one-stop shopping for research and design,” he says.

Getting High-Tech, Hands-on Experience

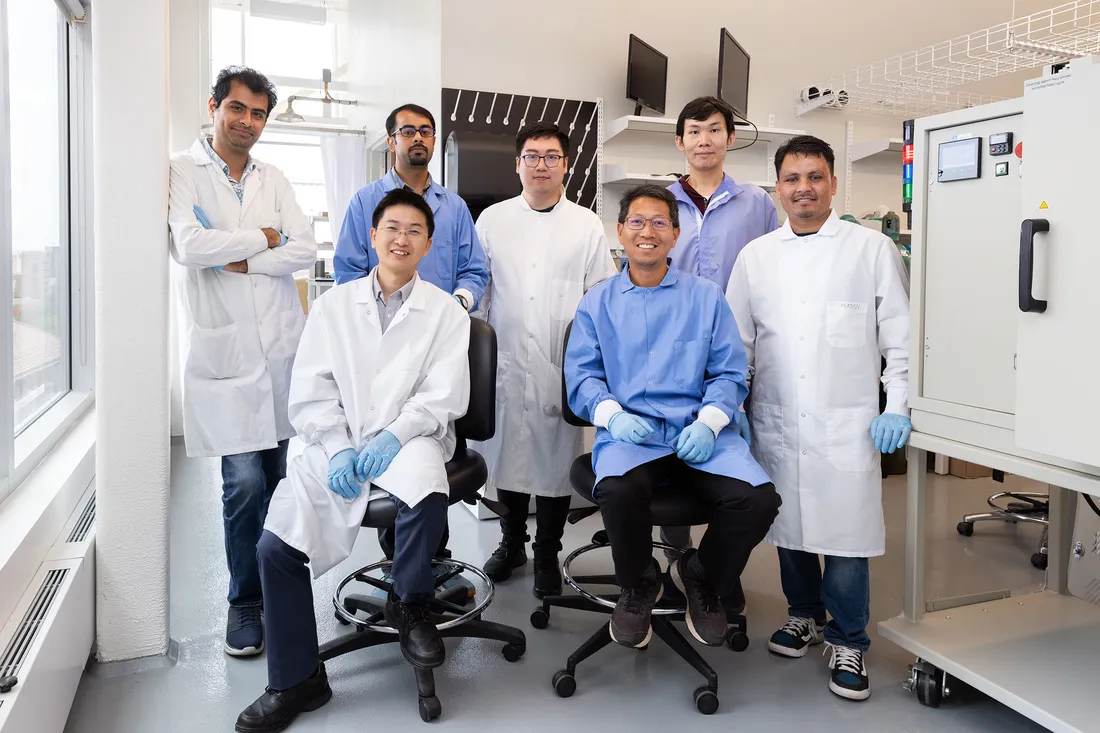

Qiao’s research team includes (clockwise from left) Ph.D. candidates Amirreza Tarafdar, Sattar, Yuchen Zhang, Hansheng Li G’18 and Madan Bahadur Saud as well as Professors Qiao and Yeqing Wang.

Hansheng Li G’18, a Ph.D. candidate in MAE, is another beneficiary of Syracuse’s lab renovation strategies. He’s currently designing magnesium-based cathode materials. (A cathode is an electrode located on the positive side of a battery cell that acquires electrons during the discharging process and releases them during charging. An anode, found on the cell’s negative side, does the opposite.) “We’re accelerating energy synthesis by almost 90%,” Li says.

Integral to his research is a high-tech microwave reactor system—a staple of all battery research labs. Such reactors look like futuristic microwave ovens, using electromagnetic waves to heat materials, but on a micrometer scale.

Li also takes advantage of Syracuse’s ultra-high-resolution scanning electron microscope (“good for observing the structure and morphology of synthesized materials”), multichannel battery testers and vacuum lamination sealer.

We’re turning today’s students into tomorrow’s leaders.

Professor Quinn Qiao

For someone who wants to someday manufacture advanced battery materials, Li sees his involvement with CEPS and the Upstate New York Energy Storage Engine as more than “yielding impactful academic outcomes.”

“I’m getting hands-on experience in fabricating batteries,” says Li, who works with Mercedes-Benz, Honda, Nissan, Carrier Global and the C4V battery technology company. “This includes developing a cost-effective, scalable process for manufacturing.”

Today’s Students, Tomorrow’s Leaders

Evidence of Syracuse’s research culture permeates Qiao’s lab, which is more of a shared workspace than an individual faculty area. Engineers rub elbows with scientists and mathematicians, while students from myriad backgrounds cut their teeth on all matter of projects.

Quinn and Wang with a “pouch battery” testing system.

Qiao shares an interest in materials science with Yeqing Wang, an assistant professor of MAE who designs and fabricates sustainable anode materials in ECS’ Composite Materials Lab. Wang transfers the anodes to Qiao’s lab, where they’re assembled into coin-cell batteries.

“We use a glovebox to build the specimens and a coin-cell battery tester to characterize and measure their charge-discharge performance,” Wang says. “By incorporating sustainable materials, like flake graphite, we reduce energy consumption during materials processing and improve battery efficiency.”

One of their students is Madan Bahadur Saud, who is designing a lithium-metal battery that could help revolutionize the EV and energy storage industries. “Our solid-state battery will hopefully outperform others in terms of cycle life, energy density and safety,” he says. The Ph.D. candidate in MAE frequently uses a planetary ball mill to grind and mix powder materials, including chemicals, into micrometer and nanometer sizes.

Saud uses a glovebox to manipulate materials in a separate environment. He’s joined by Wang, Tarafdar and Qiao.

Saud is big on doping strategies, in which he inserts trace amounts of impurities called “dopants” into battery cell electrolytes. Dopants not only increase ionic conductivity, but also improve the stability of electrodes and widen the voltage window.

None of this is possible without high-quality instruments and industry-standard methodologies, Saud explains. “They give me fresh, new insights into interfacial challenges at the atomic and microscopic levels.”

Fellow MAE Ph.D. candidate Yuchen Zhang agrees. Under Qiao’s watchful eye, he’s refining an atomic force microscopy (AFM)-based technique that could impact off-grid power systems, solar-powered vehicles and large-scale electricity generation.

Atomic force microscopy enables Qiao’s team to develop cutting-edge solar technologies.

To do this, Zhang utilizes an atomic force microscope to measure the surface topography, potential and conductivity of thin-film photovoltaic devices. Afterward, he maps their charge carrier dynamics in nanoscale dimensions. “We have a patent on a characteristic of this AFM technique,” says the solar cell specialist. “Our findings support the environmental and economic impacts of green energy.”

Qiao admits there’s a sense of urgency to these projects, that facilities are more than just tools of the trade. “We’re turning today’s students into tomorrow’s leaders,” he states. And like green technology, it’s work with educational, environmental and economic consequences.